Product description:

Hydraulic cylinders are actuators that convert hydraulic energy into linear mechanical force. They have a compact structure, high output force, and smooth operation. They are the core components for performing actions such as pushing, pulling, lifting, and pressing in various mechanical and industrial systems, and are widely used in construction machinery, metallurgy, mining, shipping, and other fields.

A Counterweight oil cylinder, also known as a hydraulic counterbalance cylinder or balance oil cylinder, is a critical hydraulic component used in cranes, excavators, concrete pump trucks, aerial platforms, and other heavy-duty machinery. Its primary function is to balance and stabilize the counterweight mechanism, ensuring smooth, controlled, and safe operation during lifting, swinging, or telescopic movements.

By providing hydraulic force to support or counteract heavy loads, the counterweight cylinder enhances machine stability, prevents tipping, and optimizes weight distribution. It plays an essential role in maintaining safety and efficiency in construction, mining, and industrial operations.

Parameters:

Product: | Hydraulic cylinder |

Maximum stroke: | Customized according to customer requirements |

Inner tube diameter: | 10mm - 500mm |

Origin: | Jiangsu, China |

Type: | Hydraulic cylinder |

Material: | Steel |

Surface treatment of piston rod: | Chrome plating |

Pipe size: | Customized according to customer requirements |

Brand: | Hengxin Zhicheng |

Size: | Customized according to customer requirements |

Certificates: | ISO9001 |

Thrust: | Maximum 42Mpa |

Colors: | Yellow / Red / Black / Blue / Green / Orange / White / Customizable |

Applicable industries: | Construction machinery / Heavy machinery / Mining industry, etc. |

Structure: | Piston type cylinder |

Advantages: | High safety level / High precision / Long service life / Automation |

Sales unit: | Per piece |

Port: | Shanghai Port or designated port |

Packaging details: | Carton, wooden box, pallet |

Payment terms: | Telegraphic transfer |

Trade terms: | EXW, FOB, CIF, DAP, DDP |

Delivery time: | 20 - 35 days |

Service: | OEM and ODM |

Piston rod: | Chrome or nickel plating, polished and ground piston rod |

Sealing type: | Parker, NOK, BUSAK SHAMBAN or according to customer requirements |

Pipe: | High-strength cold-drawn pipe, precision grinding to extend sealing life |

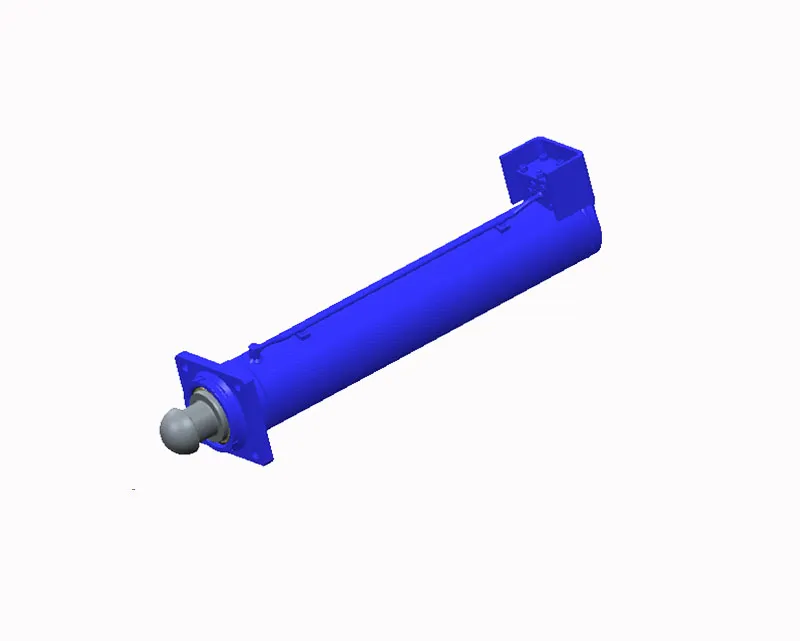

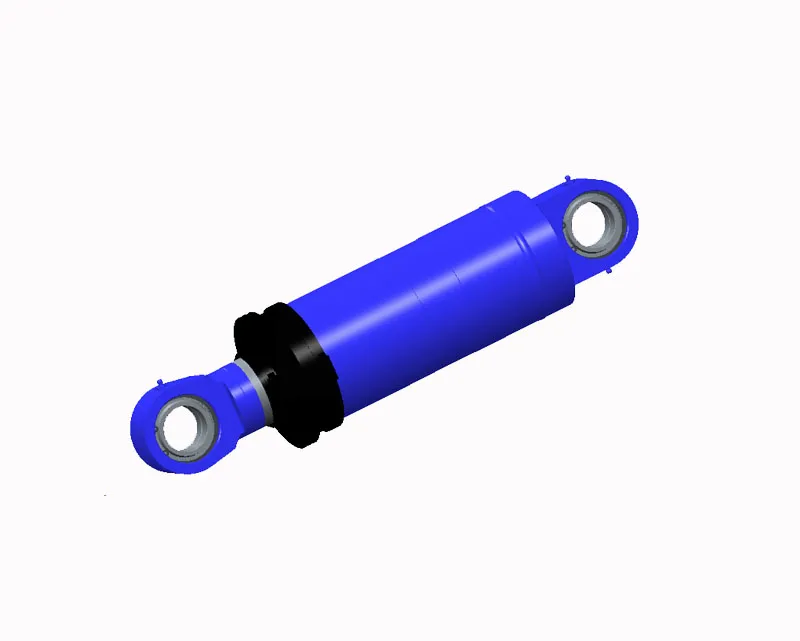

Pictures:

Working Principle and Structure

The hydraulic counterweight cylinder operates on the principle of hydraulic pressure and piston movement. When hydraulic oil is supplied to one side of the piston, it pushes the rod outward or inward, adjusting the position of the counterweight or balancing system.

This adjustment allows the equipment to compensate for load variations during operation, maintaining equilibrium and reducing vibration or structural stress.

A typical counterweight oil cylinder includes:

Cylinder barrel: Made from seamless high-strength steel for durability under pressure.

Piston and piston rod: Transfers hydraulic energy to mechanical motion.

Sealing system: Ensures zero leakage and consistent hydraulic pressure.

Mounting components: Allow secure installation on the counterweight arm or structure.

Depending on the application, the cylinder can be single-acting (gravity return) or double-acting (powered in both directions), providing flexibility and precision control.

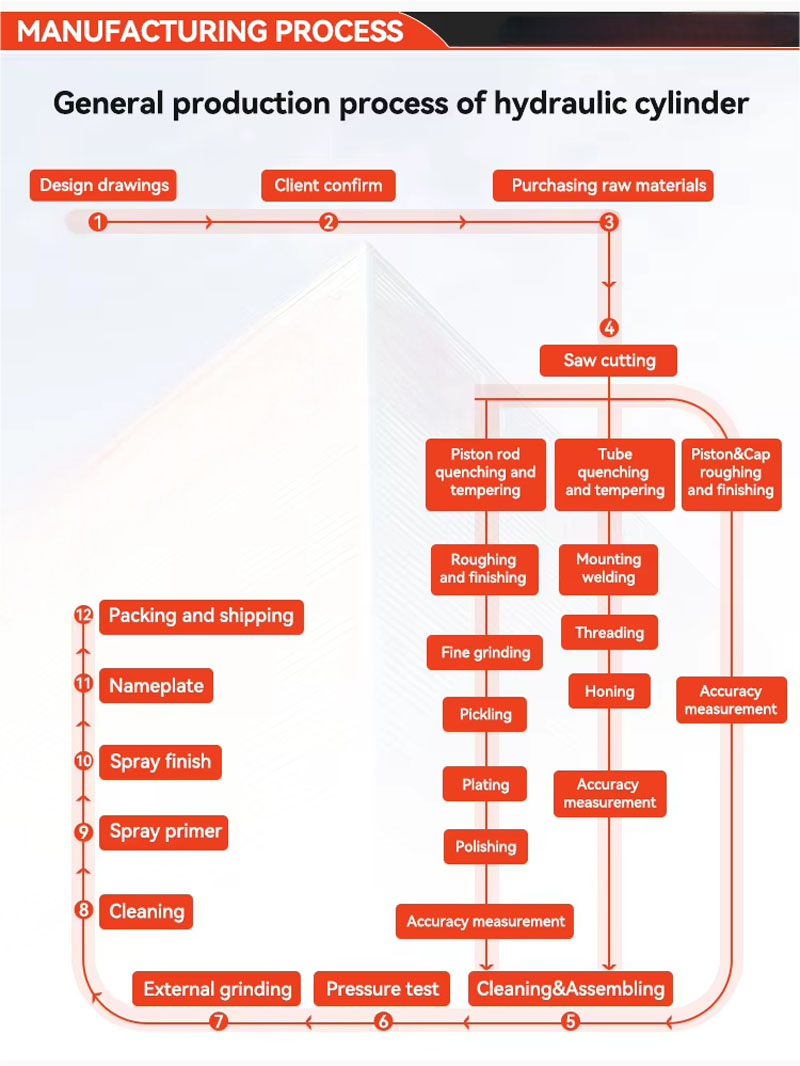

Materials and Manufacturing Process

The cylinder body is made from alloy or carbon steel precision tubes, honed and polished internally to achieve excellent surface smoothness and sealing performance. The piston rod is treated with hard chrome plating or QPQ nitriding for superior corrosion resistance and wear protection.

All parts are CNC machined with tight tolerances to ensure smooth assembly and consistent performance. The welding process utilizes robotic automation for high strength and stability.

High-quality sealing components from global brands such as Parker, Hallite, and NOK are used to provide leak-free operation and extended service life. Every cylinder is rigorously tested according to ISO 9001, DIN, and CE standards to guarantee safety and reliability.

Key Features and Advantages

High Stability and Safety: Maintains machine balance during lifting or rotating movements.

Strong Load Capacity: Designed for heavy-duty counterweight systems under high pressure.

Smooth and Precise Operation: Ensures accurate positioning and stable control.

Superior Sealing System: Prevents internal leakage and maintains consistent hydraulic performance.

Corrosion and Impact Resistance: Surface-treated rods withstand harsh environments.

Customizable Design: Available in different bore sizes, stroke lengths, and mounting configurations.

Low Maintenance: Simple structure allows easy inspection and replacement of seals.

Long Service Life: Manufactured with premium materials for reliable, long-term use.

Working principle of hydraulic cylinder:

Applications:

The hydraulic cylinder is an energy conversion device that converts hydraulic energy into mechanical energy. It is the core executive component in the hydraulic system. The hydraulic cylinder uses hydraulic oil to drive the piston to move, converting hydraulic energy into linear reciprocating motion. When the hydraulic oil enters the cylinder barrel, it pushes the piston rod to extend or retract, completing the predetermined action. The direction and speed of its movement are regulated by the hydraulic control system. The hydraulic cylinder consists of a cylinder barrel, cylinder cover, piston and piston rod, sealing device, and buffering device. According to its structure, it can be classified as piston type, plunger type, multi-stage telescopic sleeve type, and gear rack type. Hydraulic cylinders are widely used in machine tools, construction machinery, vehicles, and other fields, featuring a simple structure and smooth movement.

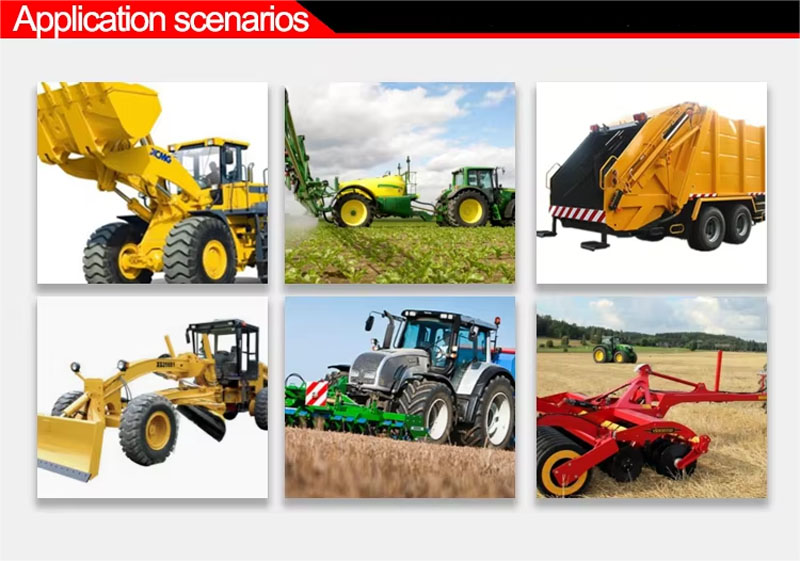

The Counterweight Hydraulic Cylinder is widely used across multiple industries, including:

Truck Cranes: Adjusts and stabilizes the counterweight during lifting operations.

Concrete Pump Trucks: Balances the rear counterweight structure for stability during pumping.

Excavators and Mining Equipment: Controls counterweight positioning during digging or swinging.

Tower Cranes and Mobile Cranes: Maintains structural balance for safe operation.

Aerial Work Platforms: Provides hydraulic support for extending or retracting counterweight mechanisms.

Material Handling Systems: Balances heavy loads in hydraulic arms and lifting platforms.

Marine and Offshore Equipment: Stabilizes ship-mounted cranes and loading systems.

Its versatility makes it a crucial component for any machinery that relies on precise hydraulic balance and stability.

Quality Assurance and Testing

Each counterweight oil cylinder undergoes strict quality inspection and performance testing before delivery:

Pressure and leakage tests under full working load.

Dimensional accuracy verification for precise assembly.

Surface hardness and coating adhesion checks to prevent corrosion.

Dynamic fatigue and endurance tests simulating real operating conditions.

Performance calibration to ensure stable extension and retraction motion.

Through these procedures, every cylinder meets the highest standards of reliability, safety, and durability.

Company profile:

Since its establishment in 2014, Wuxi Hengxin Zhicheng Co., Ltd. has rapidly grown into a leading enterprise in the steel manufacturing industry. We focus on the research, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders, and are committed to providing customers with high-quality, customizable products that fully meet diverse application needs.

Our products are exported to global markets such as the Middle East, South America, Africa, and Southeast Asia, and are highly trusted by large purchasers and customers in the steel industry. We always prioritize quality, reliability and customer service, and attach great importance to establishing long-term and stable cooperative relationships with customers. We provide each customer with tailor-made solutions.

We continuously promote technological innovation and improve service capabilities and production efficiency. Through an efficient online platform, you can browse our best-selling products at any time and communicate with the sales and support teams in real time to conveniently obtain the information you need. We sincerely invite partners from all countries to visit, exchange and provide guidance, and jointly explore more possible cooperation opportunities!

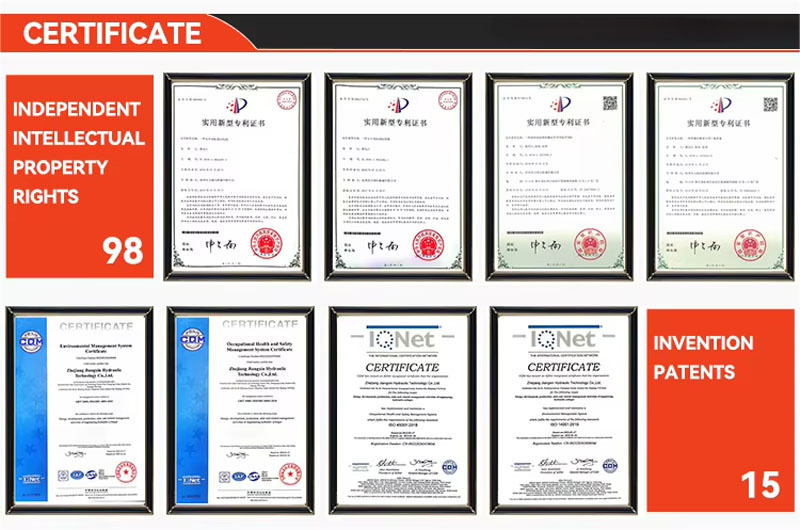

Certification:

Packaging and Transportation:

【Package standard】

We use steel bands to tightly package the products into hexagonal bundles. The structure is stable and not prone to deformation. Each bundle is equipped with two high-strength nylon straps to ensure the safety and convenience of the lifting operation.

To meet various maritime transportation needs, we offer a range of customized packaging options, including full coverage with oilcloth, moisture-proof wooden boxes, and high-strength protective frame packaging, to ensure the maximum safety of goods during transportation.

【Guarantee for transportation】

We offer 20-foot and 40-foot standard container transportation services. Each container can carry up to 25 tons of goods and we can accept trial orders with a minimum of 5 tons. This allows for flexible adaptation to your purchasing scale. All packaging complies with maritime shipping standards to ensure that the goods are delivered to the destination efficiently and safely.

Why us?

We focus on the research, development, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders. We have a complete production chain and an advanced equipment system, including piercing machines, cold drawing machines, hot rolling machines, high-precision flaw detection and testing equipment. The company has passed multiple authoritative certifications such as ISO9001, API, SGS, CCS, DNV, ABS, CE, RoHS, etc., ensuring that each product complies with international standards. We are committed to providing customers with high-quality, customizable solutions to meet diverse application needs.

Relying on our own built processing base and modern workshops, combined with multiple branches and storage centers across the country, we have achieved sufficient inventory and efficient logistics coordination, significantly shortening the delivery cycle and ensuring the rapid delivery of orders.

We have established a complete service and support system. After the order is signed, the professional after-sales team can provide timely and safe on-site guidance and technical support to ensure that customers are at ease throughout the process from procurement to use.

FAQ:

1. Do you support customized design and production?

Sure. We have a professional engineering team that can conduct customized design and production with special sizes, control systems or OEM according to your requirements.

2. How fast can you deliver?

In stock sizes, it takes 3-5 days. For customized sizes, it takes 30-35 days.

3. What payment methods do you support?

We support TT payment. Generally, 30% to 50% of the payment is made in advance, and the remaining amount is paid before shipment.

4. Can you provide material certification (MTC)?

Yes, we will provide MTC to you after production is completed to ensure that the material quality meets the standards.

5. What is the minimum order quantity?

Generally, we accept trial orders. The minimum order quantity is 1-3 tons, which can be determined according to different products.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Hak Cipta © 2025 Wuxi Hengxin Zhicheng International Trade Co., Ltd All Rights Reserved Applications

Laman web ini menggunakan kuki untuk memastikan anda mendapat pengalaman terbaik di laman web kami.