Product description:

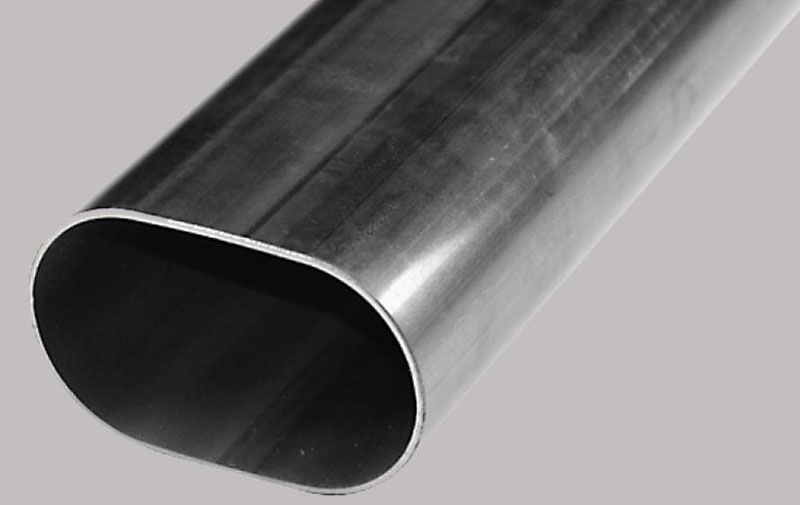

An Elliptical tube is a type of steel pipe with an elliptical cross-section, featuring unique geometric properties and mechanical advantages. It is widely used in construction, industrial equipment, and transportation fields.

An elliptical tube, also known as an oval steel tube or elliptical pipe, is a specially shaped metal tubing featuring an elliptical (oval) cross-section rather than the conventional round or square form. Its elegant appearance, superior mechanical strength, and aerodynamic profile make it an ideal choice for both structural and decorative applications.

Elliptical tubes are widely used in architectural projects, furniture design, vehicle components, mechanical structures, and sports equipment, providing an attractive combination of strength, performance, and modern style. With excellent load-bearing capacity and resistance to deformation, they offer significant advantages in both engineering and design fields.

Parameters:

Product Name: | Special-shaped Tube - Elliptical Tube |

Material: | 1010, 1020, 1045, 5140, 4130, 4140, S355 |

Tolerance: | ± 1% |

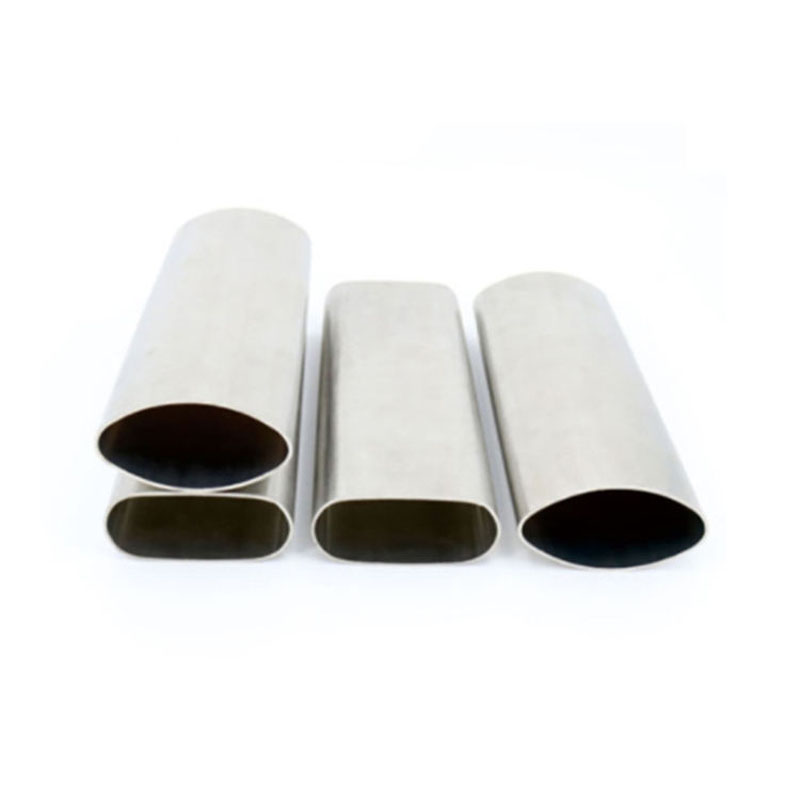

Shape: | Elliptical (Flat Ellipse / Rectangular Ellipse / Duck Egg Ellipse) |

Length: | Customized according to customer requirements |

Weighing Method: | Weighing |

Delivery Condition: | Cold state / Tempered state |

Processing Services: | Bending, Unfolding, Welding, Punching, Cutting |

Material: | Steel |

Specification: | 6*10 - 200*300 |

Wall Thickness: | 1mm - 30mm |

Diameter: | 2 - 500mm |

Length: | 5 - 12m, or customized as needed |

Standards: | GB/T3094, ASTM B210, ASTM B241, ASTM B234, JIS H4080-2006, etc. |

Process: | Extrusion / Cold Drawing |

Customization Services: | Coiled Tube, Short Cut, Bending, Punching, Titanium Coating |

Brand: | Hengxin Zhicheng |

Applicable Industries: | Construction Machinery / Heavy Machinery / Mining Industry, etc. |

Sales Unit: | Ton |

Port: | Shanghai Port or Designated Port |

Packaging Details: | Steel Strip Bundling, Wooden Box |

Payment Terms: | Telegraphic Transfer |

Trade Terms: | EXW, FOB, CIF, DAP, DDP |

Delivery Time: | 20 - 35 days |

Service: | OEM and ODM |

Minimum Order Quantity: | 1 ton |

Pictures:

Material Options

Elliptical tubes can be produced from a wide variety of materials to meet diverse requirements:

Carbon Steel (e.g., Q235, S235, AISI 1010–1045): Provides high strength and cost-effectiveness for structural use.

Stainless Steel (e.g., 304, 316, 316L): Offers outstanding corrosion resistance and a polished surface for architectural and decorative purposes.

Aluminum Alloy (e.g., 6061, 6063): Lightweight and corrosion-resistant, perfect for furniture and transportation equipment.

Alloy Steel (e.g., 4140, 4130): High tensile strength and wear resistance for heavy-duty applications.

Each material can be hot rolled, cold drawn, or extruded depending on performance and precision requirements.

Manufacturing Process

The production of elliptical tubes involves advanced forming and finishing processes to ensure dimensional accuracy, smooth surfaces, and consistent wall thickness. The main steps include:

Raw Tube Preparation: Start with seamless or welded round tubes.

Forming: The round tube is shaped into an elliptical cross-section using precision molds or rollers.

Heat Treatment: Applied to relieve internal stress and enhance mechanical properties.

Cold Drawing: Ensures tighter tolerances and smoother surfaces.

Surface Finishing: Polishing, pickling, sandblasting, or coating improves appearance and corrosion resistance.

Quality Inspection: Verifies straightness, size accuracy, and surface integrity.

These processes guarantee that every elliptical tube meets international quality and performance standards.

Key Features and Advantages

Aesthetic Design: Smooth elliptical profile suitable for modern architecture and interior design.

High Structural Strength: Excellent resistance to bending and torsional stress.

Aerodynamic Efficiency: Reduced air resistance for vehicle and mechanical applications.

Smooth Surface Finish: Ideal for decorative installations.

Versatile Fabrication: Can be easily bent, cut, welded, or drilled.

Corrosion and Weather Resistance: Especially strong when made from stainless or coated steel.

Lightweight with High Load Capacity: Provides strength without adding excess weight.

In stock:

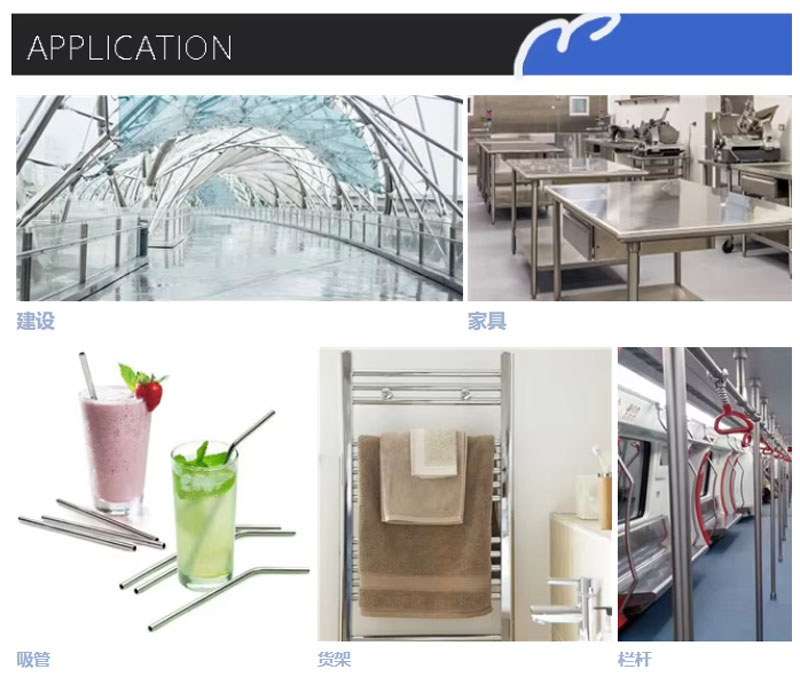

Application:

The elliptical tube is suitable for a wide range of applications that demand both strength and aesthetic value:

Architecture and Construction: Used for handrails, balustrades, support columns, canopies, and curtain wall structures.

Furniture and Interior Design: Frames for tables, chairs, and modern fixtures.

Automotive Industry: Applied in vehicle frames, exhaust systems, and structural components.

Sports and Fitness Equipment: Frames for exercise machines, bicycles, and outdoor installations.

Heat Exchangers and Fluid Systems: Elliptical tubes provide improved flow and heat transfer efficiency.

Marine and Transportation Sectors: Used in shipbuilding and lightweight vehicle designs.

Because of their versatility and elegance, elliptical tubes have become a popular alternative to conventional round and square pipes.

Company profile:

Since its establishment in 2014, Wuxi Hengxin Zhicheng Co., Ltd. has rapidly grown into a leading enterprise in the steel manufacturing industry. We focus on the research, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders, and are committed to providing customers with high-quality, customizable products that fully meet diverse application needs.

Our products are exported to global markets such as the Middle East, South America, Africa, and Southeast Asia, and are highly trusted by large purchasers and customers in the steel industry. We always prioritize quality, reliability and customer service, and attach great importance to establishing long-term and stable cooperative relationships with customers. We provide each customer with tailor-made solutions.

We continuously promote technological innovation and improve service capabilities and production efficiency. Through an efficient online platform, you can browse our best-selling products at any time and communicate with the sales and support teams in real time to conveniently obtain the information you need. We sincerely invite partners from all countries to visit, exchange and provide guidance, and jointly explore more possible cooperation opportunities!

Certification:

Packaging and Transportation:

【Package standard】

We use steel bands to tightly package the products into hexagonal bundles. The structure is stable and not prone to deformation. Each bundle is equipped with two high-strength nylon straps to ensure the safety and convenience of the lifting operation.

To meet various maritime transportation needs, we offer a range of customized packaging options, including full coverage with oilcloth, moisture-proof wooden boxes, and high-strength protective frame packaging, to ensure the maximum safety of goods during transportation.

【Guarantee for transportation】

We offer 20-foot and 40-foot standard container transportation services. Each container can carry up to 25 tons of goods and we can accept trial orders with a minimum of 5 tons. This allows for flexible adaptation to your purchasing scale. All packaging complies with maritime shipping standards to ensure that the goods are delivered to the destination efficiently and safely.

Why us?

We focus on the research, development, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders. We have a complete production chain and an advanced equipment system, including piercing machines, cold drawing machines, hot rolling machines, high-precision flaw detection and testing equipment. The company has passed multiple authoritative certifications such as ISO9001, API, SGS, CCS, DNV, ABS, CE, RoHS, etc., ensuring that each product complies with international standards. We are committed to providing customers with high-quality, customizable solutions to meet diverse application needs.

Relying on our own built processing base and modern workshops, combined with multiple branches and storage centers across the country, we have achieved sufficient inventory and efficient logistics coordination, significantly shortening the delivery cycle and ensuring the rapid delivery of orders.

We have established a complete service and support system. After the order is signed, the professional after-sales team can provide timely and safe on-site guidance and technical support to ensure that customers are at ease throughout the process from procurement to use.

FAQ:

1. Do you support customized design and production?

Sure. We have a professional engineering team that can conduct customized design and production with special sizes, control systems or OEM according to your requirements.

2. How fast can you deliver?

In stock sizes, it takes 3-5 days. For customized sizes, it takes 30-35 days.

3. What payment methods do you support?

We support TT payment. Generally, 30% to 50% of the payment is made in advance, and the remaining amount is paid before shipment.

4. Can you provide material certification (MTC)?

Yes, we will provide MTC to you after production is completed to ensure that the material quality meets the standards.

5. What is the minimum order quantity?

Generally, we accept trial orders. The minimum order quantity is 1-3 tons, which can be determined according to different products.

RELATED

RELATED

Hak Cipta © 2025 Wuxi Hengxin Zhicheng International Trade Co., Ltd All Rights Reserved Applications

Laman web ini menggunakan kuki untuk memastikan anda mendapat pengalaman terbaik di laman web kami.